Omega Products has many different textured finishes that can create a wide variety of appearances. Each finish has a unique combination of properties with advantages and limitations. These properties may make a finish a better or more desirable option for a project. Below is a discussion of each finish’s properties and relative performance. This information can be used to help determine which product to select. Note, it is recommended that a professional plaster applicator be involved in the final selection of the product, texture, and color.

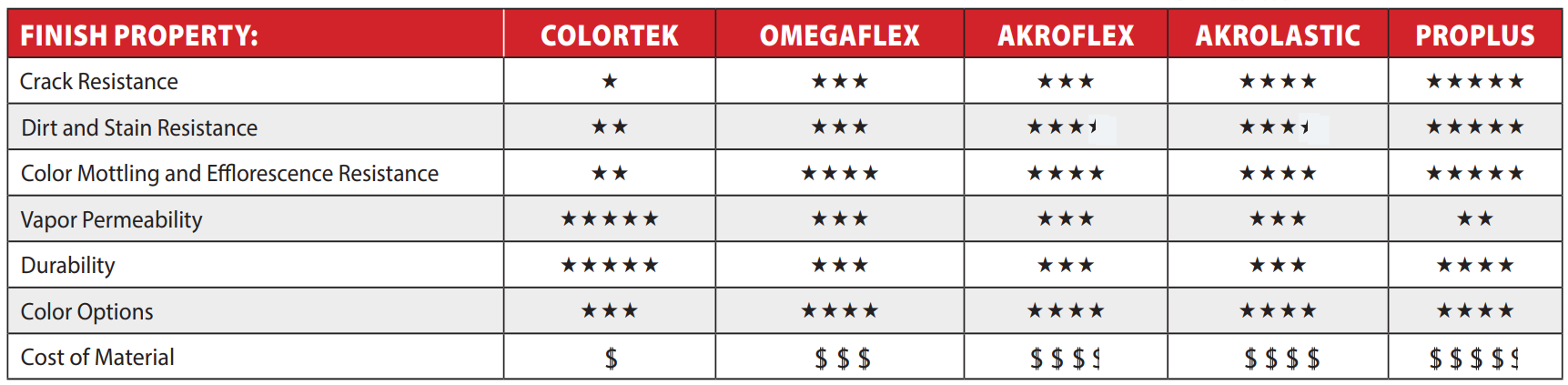

Table 1 compares the performance of the five most popular Omega finishes. There are seven properties listed with the relative performance for each finish shown; the higher the number of stars, the better the performance. More detailed information on these properties will be provided below. When selecting a finish, one should try to match the needs and budget of the project to the best finish option.

Table 1: Textured Finishes Comparison. This chart compares the relative performance of the finish options.

Cement-based Finishes v. Acrylic-based Finishes

Omega’s finishes can be divided into two general product types: cement-based stucco finishes or acrylic-based textured finishes. Both types of finishes can achieve similar, though not identical, appearances, but they have distinct advantages and limitations that should be considered when making a selection. Below is a table that compares the two finish types. This table is similar to Table 1, but includes more performance details and discusses the broader finish category rather than individual products.

Table 2. Comparison of cement-based finishes versus acrylic-based finishes.

| Property: | Cement-based | Acrylic-based |

|---|---|---|

| Crack Resistance | Cement is brittle and prone to cracking. | Acrylic resins allow for some flexibility to reduce cracking in the finish. AkroLastic has improved flexibility and ProPlus has the highest level. |

| Dirt and Stain Resistance | Cement-based finishes can remain beautiful for decades. However, cement is porous, which makes it more susceptible to staining. The likelihood of staining can be reduced by painting or sealing. | Omega’s acrylic finishes use the latest Dirt Pickup Resistance (DPR) technology to help prevent staining. ProPlus uses the enhanced DPR. |

| Color Mottling | Cement-based finishes are suspectable to color mottling during the initial curing process. To fix the mottling, the finish can be painted or fog coated. | Acrylic-based finishes are uniform in color (like paint) and are not prone to color mottling. |

| Efflorescence Resistance | Cement-based products are inherently prone to efflorescence; see Omega’s bulletin on efflorescence to learn more. | Acrylic-based finishes do not effloresce. |

| Vapor Permeability | Cement is naturally permeable. | Acrylic-based finishes have some permeability, but less than cement finishes. |

| Durability | Cement-based finishes are very durable and can last many decades with minimal maintenance. | Acrylic-based finishes are durable and will last for decades if properly maintained. |

| Color Options | Cement-based finishes have wide color pallet, but are not possible in very dark or some bright, organic colors. | Acrylic-based finishes are available in a very wide range of colors, including dark and bright, organic colors. |

| Cost of Materials | Cement-based finishes are the most economical finishes to apply and maintain. | Acrylic-based finishes have a higher material cost compared to cement-based finish. |

Cement-based Finishes

See all cement-based finishes here.

ColorTek

ColorTek is a premium, factory-blended family of cement-based finishes that are very similar to the traditional stucco finishes that have been used for hundreds of years. These economical finishes are one of the longest-lasting, most durable, lowest maintenance exterior cladding options. In addition, they are naturally fire, impact, and insect resistant.

ColorTek is manufactured using cement, hydrated lime, graded aggregates, and proprietary performance-enhancing additives. It comes in five aggregate combinations, shown on the textures page, that allow design flexibility and a variety of finish textures.

ColorTek stucco is available in Base 2 (grey), Base 10 (white), Base 1 (white/grey), and Base 5 (dark grey), which may be colored in the field using the Omega ColorPak System. Alternatively, ColorTek is offered as a factory mixed colored stucco; minimum quantities may apply when ordering factory-blended products.

Learn more about the ColorTek options:

Travertino

Travertino is a cement-based interior/exterior finish designed to achieve a variety of sedimentary stone appearances, such as travertine, limestone, and sandstone. Its texture can range from distressed to smooth and can be carved or cast into shapes. Travertino is an excellent choice to create a beautiful, warm stone appearance with a lower cost, lower weight, and shorter lead time than real stone.

Learn more here.

Acrylic-based Finishes

Omega’s acrylic-based finishes use high-quality acrylic resin mixed with graded aggregates to create textured finishes that appear similar to traditional stucco finish. Acrylic-based textured finishes have improved resistance to cracking, moisture, efflorescence, and staining compared cement-based stucco. They incorporate Dirt Pickup Resistance (DPR) technology that minimizes dirt accumulation for easy maintenance and are less prone to color modeling.

Omega’s acrylic finishes are available in three different bases: pastel for light medium colors, tint for medium to dark colors, and accent for darker colors. These bases can be colored using the Omega Color Bottle system or factory tinted.

Omega offers four categories of acrylic finishes that are described below. Each of these categories has a wide variety of textures that are shown on the acrylic textures page.

AkroFlex

AkroFlex Finishes are designed for Omega’s commercial EIF systems. AkroFlex can also be applied over three coat and one-coat stucco systems.

The links below are for the different AkroFlex finish texture options. The differences between the textures are the size and types of aggregates used.

AkroLastic

AkroLastic Finishes are textured elastomeric finishes that provide greater weather resistance and elasticity compared to standard acrylic finishes, which allows it to bridge hairline cracks. AkroLastic is available in all AkroFlex standard textures.

Learn more about AkroLastic finishes here.

AkroLastic ProPlus

AkroLastic ProPlus Finishes are Omega’s most advanced textured finishes. ProPlus offers improved elasticity, weather resistance, and stain resistance compared to standard acrylic and elastomeric finishes.

Learn more about AkroLastic ProPlus here.