MAVS is a family of mortars and grouts used for installing adhered veneer, as well as setting traditional full brick and block. MAVS bonding mortars are designed to handle the more popular veneers being designed and specified today such as: large format natural & manufactured profiles, porcelain tile, thin brick, dry stacked, planks and many others. These veneers require high quality polymer-modified mortars, specially formulated for demanding applications. Veneer manufacturers are requiring that installers use polymer-modified mortars that meet the requirements outlined in ANSI A118.4 or A118.15 standards for many of their profiles. MAVS provides options that meet and exceed all of these ANSI requirements.

One of the greatest features of MAVS is the industry-leading warranties that can be integrated with Omega’s wall system products. These exceptional wall system warranties incorporate Omega’s already proven wall assemblies with our high performing MAVS bonding mortars to cover the entire wall from brown coat to veneer. These amazing warranties along with our exceptional customer service makes MAVS and Omega the Professionals Choice. MAVS may be Omega’s newest product line, however Omega has been manufacturing modified mortars, grouts and hundreds of high quality products for almost 50 years.

Premium, Yet Practical Solutions For Your Masonry Needs

Downloads

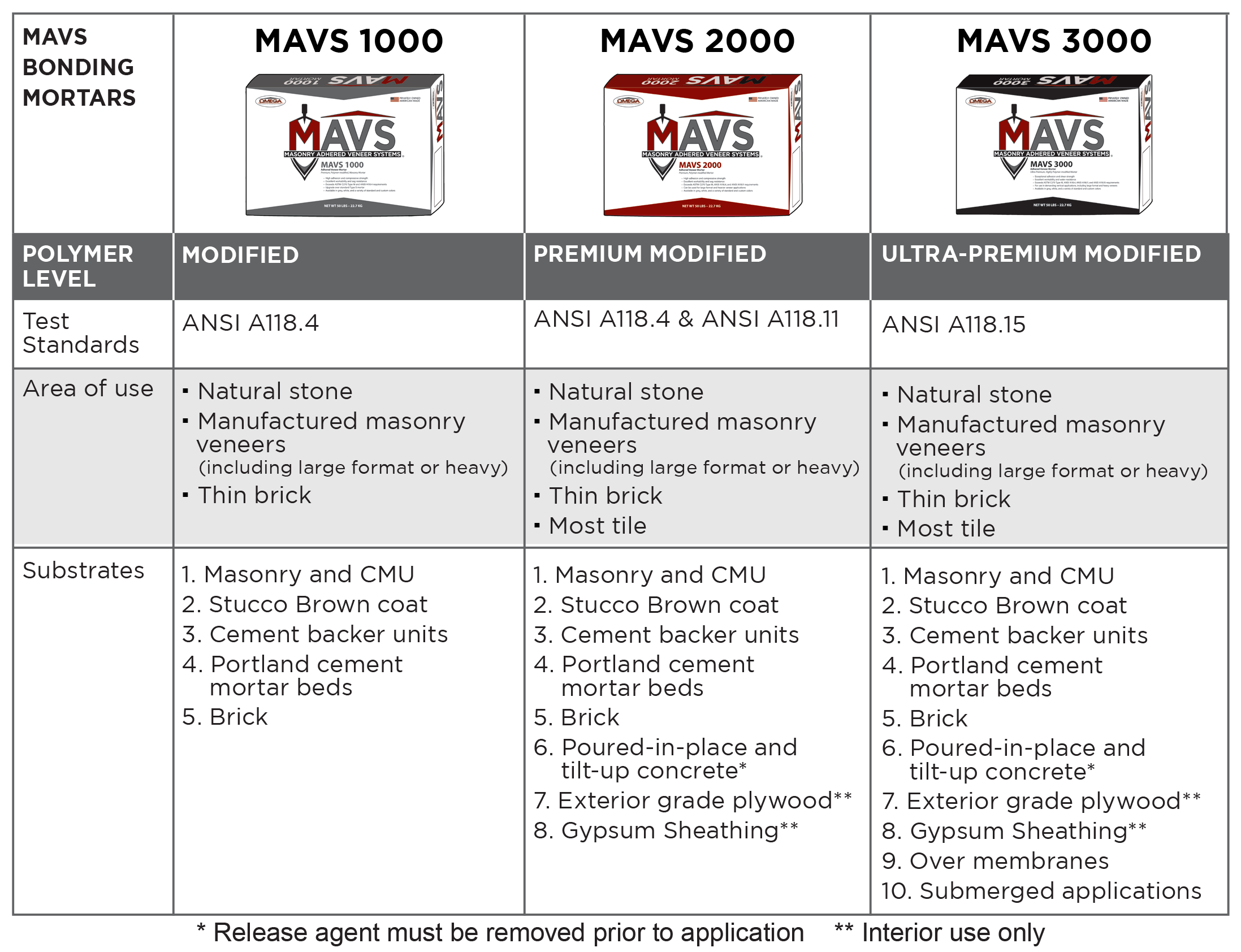

Choosing a MAVS Bonding Mortar

Select the level of performance, sand profile, and color

MAVS bonding mortars offer a selection of polymer modification, sand profiles, and colors which gives applicators and design professionals the options needed to meet the requirements for a wide variety of veneer applications.

Performance

All MAVS bonding mortars are polymer-modified and use specialty additives to improve performance. MAVS offers three levels of bonding mortars:

- MAVS 1000 – Good, exceeding the requirements of ANSI A118.4

- MAVS 2000 – Better, exceeding the requirements of ANSI A118.4 & A118.11

- MAVS 3000 – Best, exceeding the requirements of ANSI A118.15

Sand Profile

MAVS bonding mortars are available in two sand profiles:

- Standard – Masonry sand similar to Type S mortars

- Fine – Finer sand similar to thin set mortars

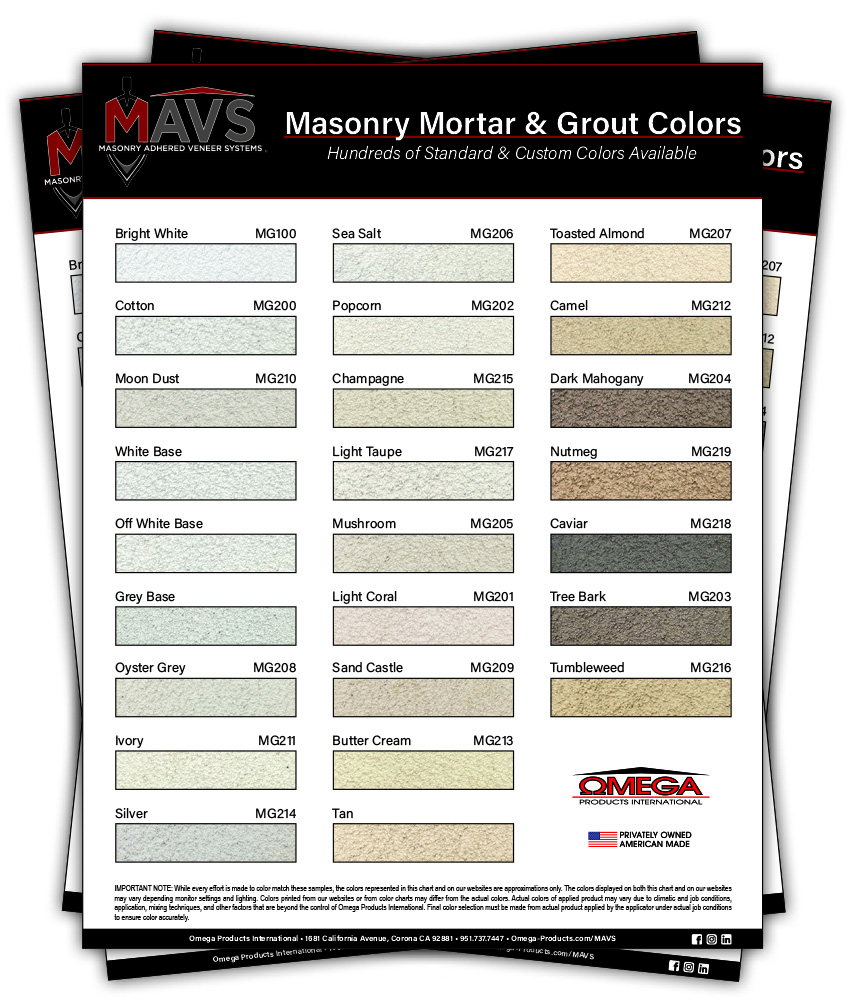

Colors

MAVS bonding mortars are available in a variety of standard and custom colors.

- Standard base colors: grey, white, off white, and tan

- Custom color matching available to meet all your project needs

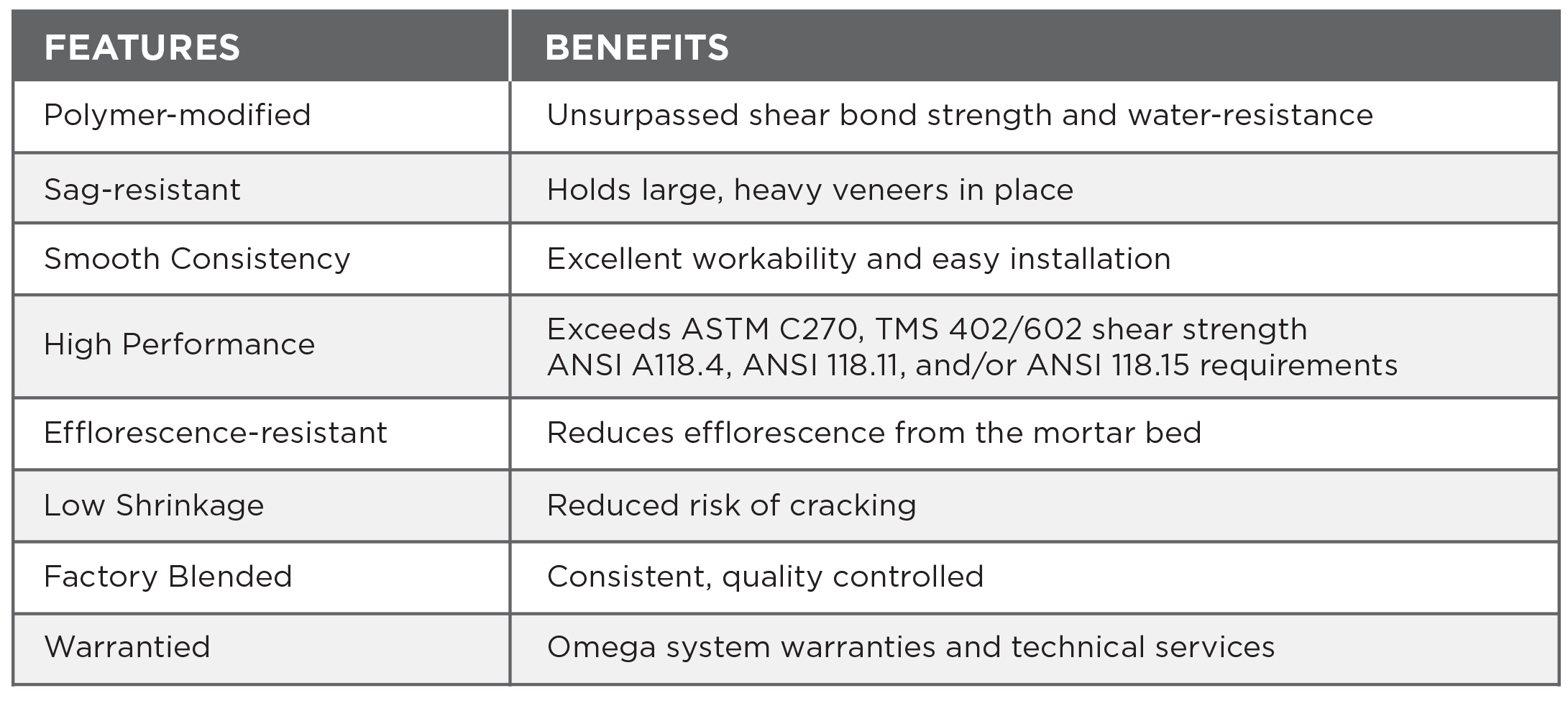

MAVS Bonding Mortars Features and Benefits

Testing and Performance

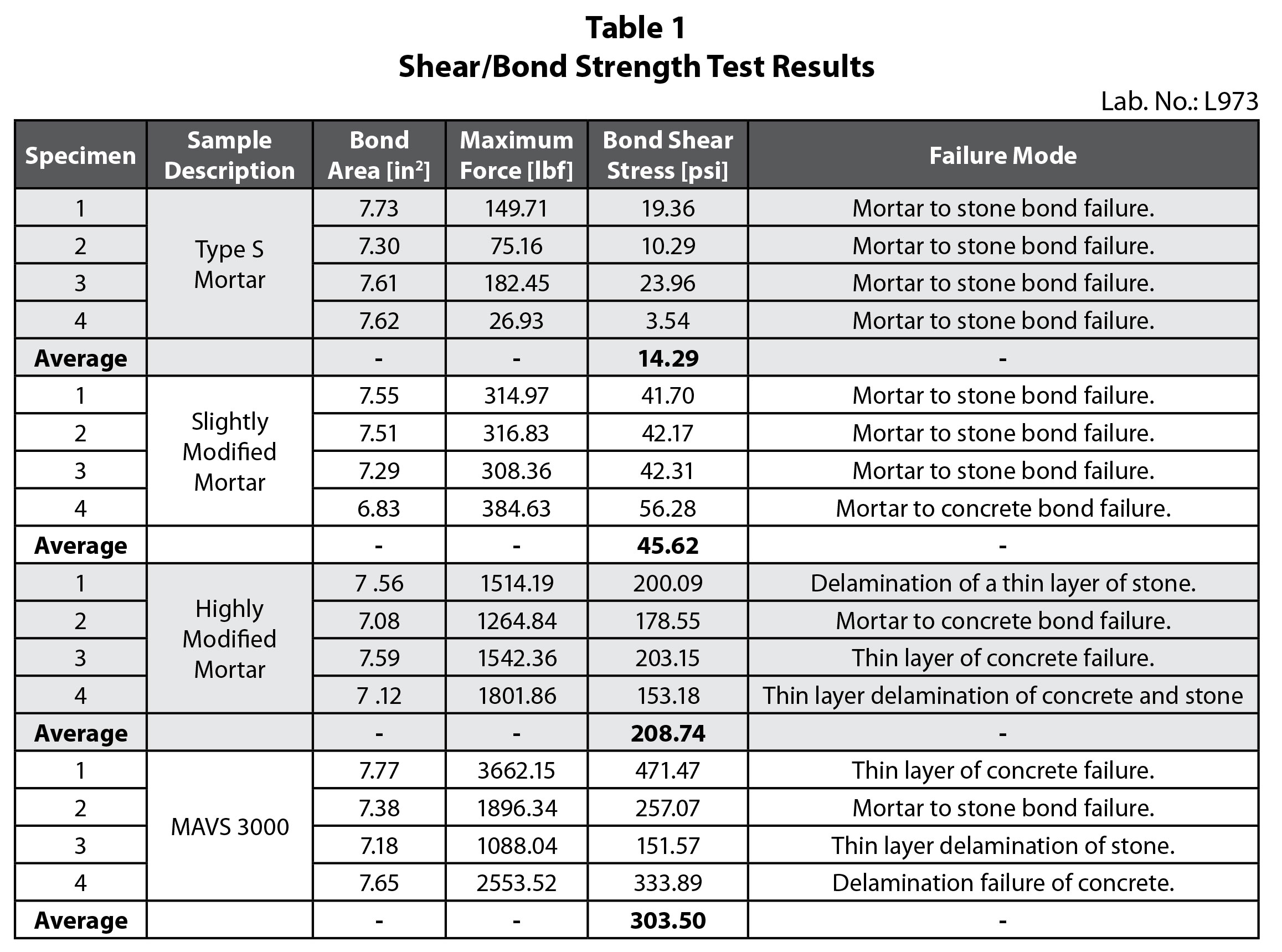

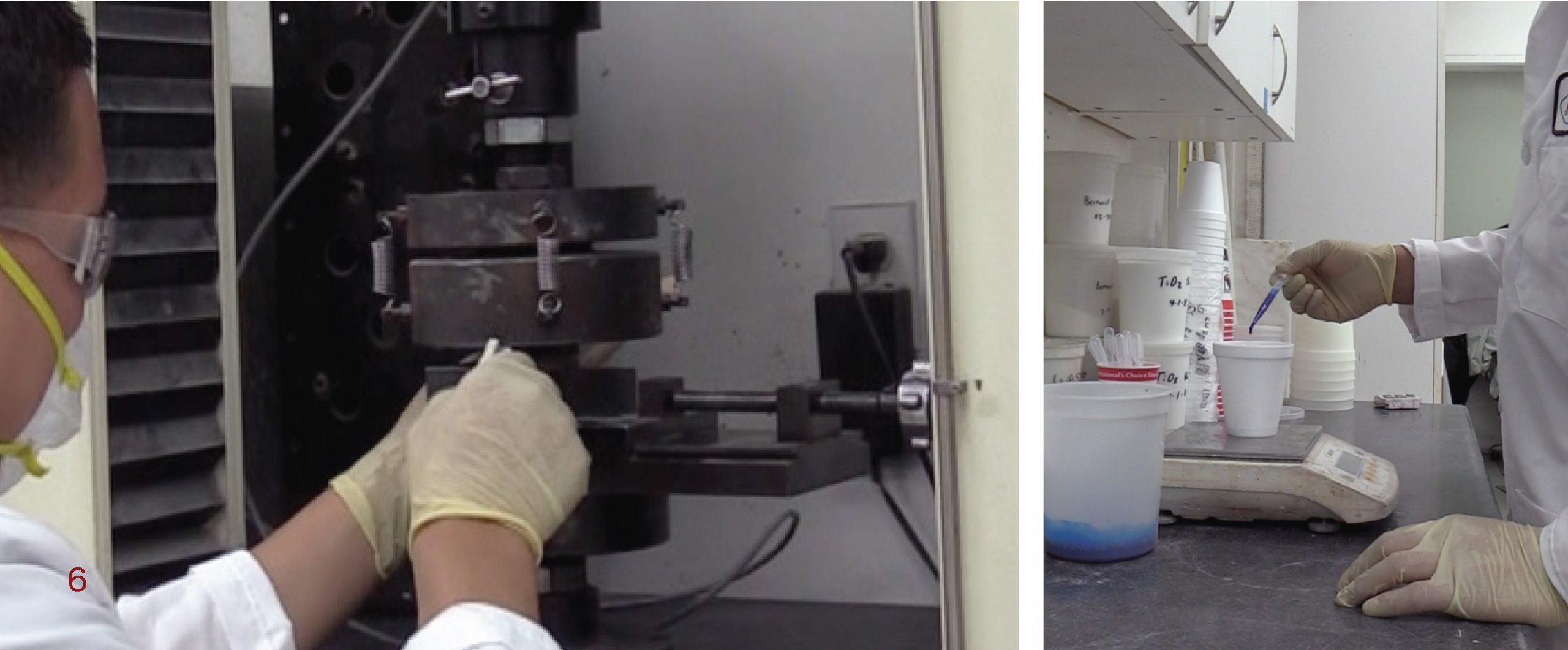

Third-Party Testing

MAVS products have been extensively tested with industry-leading results. MAVS Bonding Mortars have been formulated to perform exceptionally in the most demanding adhered veneer projects.

Third-party ASTM C482 shear bond testing results in the chart below shows the MAVS 3000 bonding mortar outperforming competitor mortars such as an ASTM C270 Type S, a slightly modified A118.4 mortar, and a highly modified A118.15 mortar.

Field Performance Testing

The MAVS bonding mortars have not just been tested in labs. They have also been third-party tested in the field to verify real-world performance. Below are results from a third-party field test that compared MAVS 3000 versus a competitor’s ANSI A118.15 mortar. Once again, MAVS was shown to outperform competitor products.

Performing

the pull test

MAVS 3000 sample pulls the brown coat to the lath

Competitor’s sample fall at the mortar and brown coat interface

All MAVS samples pull the brown coat to the lath

Non-modified and Modified Mortars

There are many different mortars used in the masonry industry. Some mortars are commonly known as Type S or non-modified mortars used for setting or grouting, while others are commonly known as polymer-modified mortars used for bonding.

Non-modified Mortars

Non-modified mortars are typically made using portland cement, lime, and sand. They are used for setting brick, block and for grouting joints between veneer. Non-modified mortars have the following characteristics:

- Conform with ASTM C270, standard specification for mortar for unit masonry

- Traditionally known as standard Type S

- Allows for field mixed mortars

- Works well for grouting and setting full brick and block

MAVS Masonry Mortar & Grout

MAVS Masonry Mortar & Grout is a non-modified premium mortar used for setting brick, block, and for grouting natural and manufactured veneers, thin brick, pavers, stone, precast, brick, and block. Exceeds ASTM C270 Type S and ANSI A118.6 grout requirements.

MAVS Masonry Mortar & Grout is available in grey, white, off white, tan, and a variety of standard and custom colors.

Modified Mortars

Modified mortars contain portland cement and aggregate, but are also modified with polymers and specialty additives to improve:

- Workability

- Sag-resistance

- Water-retention

- Setting times

The level of polymer-modification is one of the most important factors in the performance of a bonding mortar. Often the modification level is measured by the ANSI A118 testing standard it is able to pass:

- ANSI A118.1: Non-modified

- ANSI A118.4: Minimally modified

- ANSI A118.11: Modified

- ANSI A118.15: Highly modified

Modified veneer bonding mortars are formulated specifically for today’s more common and challenging adhered veneer applications.

Advantages of Highly Modified Mortar

- High adhesion and early strength

- Greater flexural and tensile strength

- Reduced water permeability

- High compressive strength

- Resistance to freeze thaw cycling

- Reduced shrinkage and cracking

- Higher bond strength and durability

- Holds large, heavy veneers in place

ALL MAVS BONDING MORTARS ARE POLYMER-MODIFIED

Veneer & Mortar Examples

Why do we need different types of mortars?

Today’s veneer and substrates all have different physical properties. Some of the important properties to take into consideration are density, porosity (absorption), size, and weight. These differences require specifically formulated mortars to ensure a successful installation. For example, large format porcelain tiles require a highly polymer-modified mortar with excellent sag resistance and greater adhesive strength that complies with ANSI A118.15. While clay thin brick veneer or small manufactured stone veneer, which are both porous and lighter weight only require a lower modified ANSI A118.4 mortar. The following sections have some examples of different types of veneer, their physical properties, and the corresponding MAVS Bonding Mortars that can be used to install them.

Examples of Veneer for ANSI A118.4 Bonding Mortars

Veneers that are fairly porous, 5% – 10% absorption rate. Smaller and/or lighter veneers, such as these examples:

- Manufactured stone: smaller sizes, such as 4”x8”, 6”x10”, 2”x12”

- Thin natural stone: smaller sizes that are approx. 1/2” thick and 6” to 8” long

- Thin brick: manufactured or cut that are not high fired

Examples of Veneer for ANSI A118.11 Bonding Mortars

Veneers that are less porous, 2.5% – 4% absorption rate. Moderate in size and/or weight veneers, such as these examples:

- Manufactured stone and plank veneers, approx. 12” x 24″ to 8” x 36”

- Thin brick that are medium to high fired

- Natural stone medium size, Z panels, quick fit panels

Examples of Veneer for ANSI A118.15 Bonding Mortars

Veneers that are dense, not porous, .05% – 2.9% absorption rate. Larger in size and/or weight veneers, such as these examples:

- Porcelain tile, large or heavy veneer, and longer plank style veneers

- Natural stone large/heavy in size, veneers close to 15 lbs/sf

- High fired, or iron spot brick veneer, glass tiles, dense stone

Omega Wall System Warranties

One of the unique features of MAVS is the industry-leading warranties that can be integrated with Omega’s wall system products. These exceptional wall system warranties incorporate Omega’s already proven wall assemblies with our high-performing MAVS bonding mortars.

Adhered veneer is often being installed over Omega Super Cement Three Coat system or Omega Diamond Wall One Coat system. When using MAVS to install veneer, the builder or owner receives veneer bonding mortars that are verified to perform over Omega wall systems, plus the integrated warranty that covers the wall assembly from the scratch coat to the veneer. The warranty length depends on the combination of Omega products used.

MAVS over Super Cement Wall System

MAVS over Diamond Wall System

Additional MAVS Warranties

Omega offers industry leading warranties when MAVS bonding mortars are used over other types of approved wall assemblies. Some of the more common substrates include; CMU, tilt-up or poured in place concrete, manufactured approved cement board, and brick.

CMU, Tilt-up, and Poured-in-Place Warranty

Approved Cement Board Warranty

* NOTE: All substrates must be free of dirt, oil, release agents, paint, or anything that is considered a bond breaker. They must be removed prior to the installation of bonding mortar. Sandblasting or bead blasting is required. Pressure washing is not acceptable.

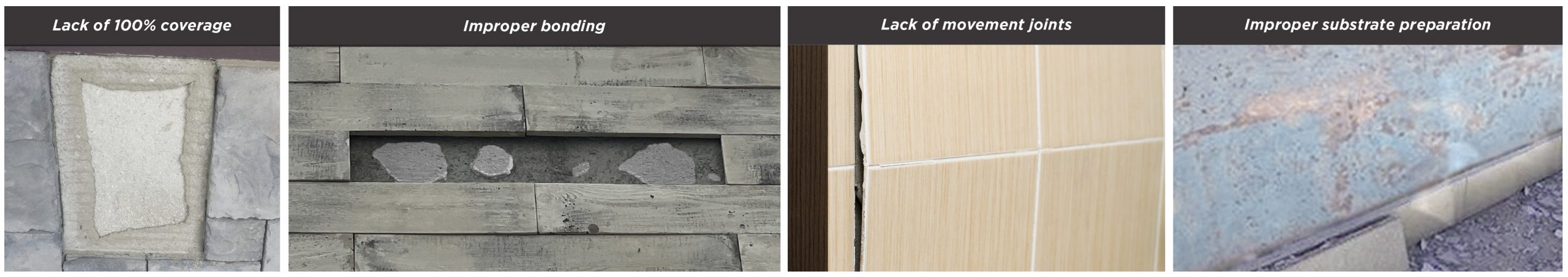

Proper Installation Practices

Along with selecting the proper mortar for a particular adhered veneer project, it is critical that proper installation practices are followed. Some of the veneers available today are much more challenging to install than the veneer from the past. Some of the traditional installation methods and mortars that were used in the past are now causing failures. The following are some proven installation methods and additional resources that will help to have a successful veneer installation.

- All veneers must be installed using proper installation methods, consisting of:

- A wet-to-wet bond.

- Back buttering each veneer. Do not spot bond.

- Ensuring 100% coverage between the veneer and the properly prepared substrate.

- Substrate and back of veneer receiving bonding mortar must be free of dirt, dust, debris, oil, paint, release agent, or anything that can hinder proper bond.

- Proper movement joints and control joints should be in place to avoid veneers from buckling or tenting.

- Verify the veneer and grout color match through a job site mock-up using all the specified products and colors prior to the actual installation.

- Verify through the veneer manufacturer that the veneer can be used for the specified application. For example; not all veneers can be used exterior, or as a vertical wall facade.

MAVS & Colors

MAVS Masonry Mortar & Grout is used for setting brick, block and for grouting manufactured and natural veneers, thin brick, pavers, stone, precast, brick and block. Exceeds ASTM C270 Type S and ANSI A118.6 grout requirements.

MAVS Adhesive Sealant is used to fill in expansion and control joints. It is non-sag, fast drying, UV resistant, and has exceptional elongation.

MAVS Masonry Mortar & Grout and MAVS Adhesive Sealants can be manufactured in hundreds of standard and custom colors

(additional charges may apply)